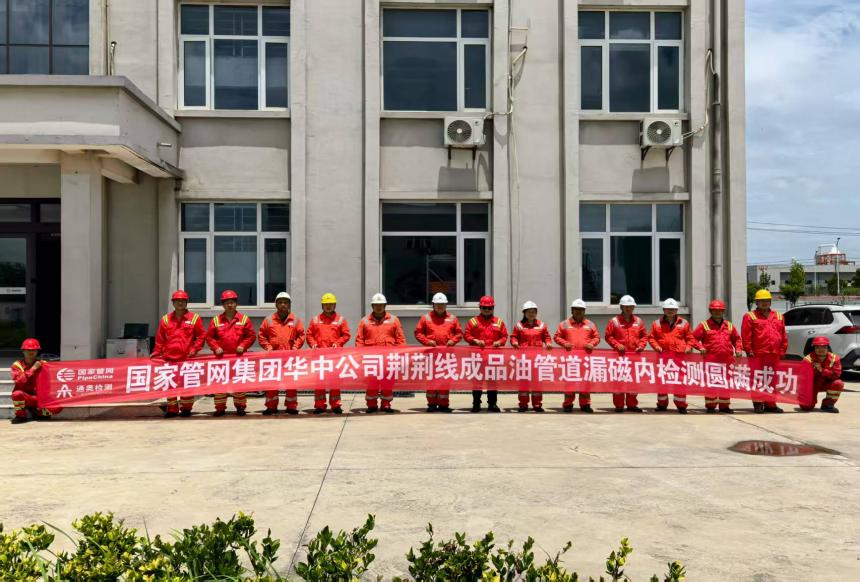

Recently, T-ALL Inspection Group has successfully completed the internal inspection of the Jingjing Pipeline for National Pipeline Network Central China Company. This operation, which underwent several days of meticulous preparation, scientific organization, and efficient implementation, ultimately achieved all inspection tasks successfully! This accomplishment not only serves as a "booster shot" for the safe operation of the "vital artery" for refined oil transportation in Central China but also, through solid technological practices, demonstrates T-ALL Inspection's professional commitment and robust capabilities in the field of regional energy inspection and supply assurance.

To comprehensively understand the "health status" of the pipeline and precisely identify hidden risks, this operation employed the mature and efficient magnetic flux leakage (MFL) internal inspection technology in the current field of pipeline non-destructive testing. This technology relies on intelligent inspection equipment equipped with high-precision sensors, which can "traverse and inspect" inside the pipeline along with the refined oil medium. It is like equipping the pipeline with an "intelligent physical examination device," capable of precisely capturing potential safety hazards such as local corrosion of the pipe wall, metal loss, and weld defects. Additionally, it can simultaneously record key data including the location, size, and severity of defects, providing detailed and reliable scientific support for subsequent pipeline health management. At the operation site, T-ALL Inspection and National Pipeline Network Central China Company adhered to the principle of "collaborative tackling tough challenges and quality first" and swiftly formed a cross-unit special task team. Central China Company fully leveraged its own advantages, taking charge of coordinating pipeline transportation and on-site safety management to ensure that the entire inspection process did not disrupt the normal operation of the pipeline. T-ALL Inspection, on the other hand, deployed its core technical team and customized inspection equipment to provide solid technical support for the inspection operation. Both parties integrated resources, complemented each other's strengths, and advanced the operation on-site throughout the entire process. Technical personnel strictly adhered to the highest industry standard procedures, conducting repeated checks and striving for excellence in every operational step, from pre-operation debugging of inspection equipment and precise calibration of core parameters to real-time data transmission and dynamic monitoring within the pipeline. In the high-pressure, long-distance pipeline environment, the inspection equipment operated efficiently, ultimately achieving "inspection without stopping transportation and uninterrupted supply assurance," minimizing the impact on the normal energy supply along the route. This close collaboration not only ensured the quality of the operation but also vividly demonstrated the "win-win cooperation" partnership in the field of energy supply assurance. The successful completion of this inspection has enabled T-ALL Inspection, through its professional technology and rich experience, to provide precise bases for the maintenance plan of the Jingjing Pipeline, lay a solid foundation for the long-term safe operation of the pipeline, accumulate practical experience in refined oil pipeline health management, and showcase its leading position in the industry. In the future, driven by technological innovation and guided by a sense of responsibility, T-ALL Inspection will iteratively upgrade its inspection, operation, and maintenance technologies, deepen cooperation with industry partners, and make every effort to safeguard the safety of refined oil transportation, contributing to regional energy supply assurance.