On October 1, 2024, the Dina Oil and Gas Production Management Area of Tarim Oilfield completed the acceptance of the foam geometry internal inspection project for the Dina Φ457 bimetallic composite pipe, marking T-ALL Inspection's successful delivery of another bimetallic composite pipe lining collapse internal inspection project.

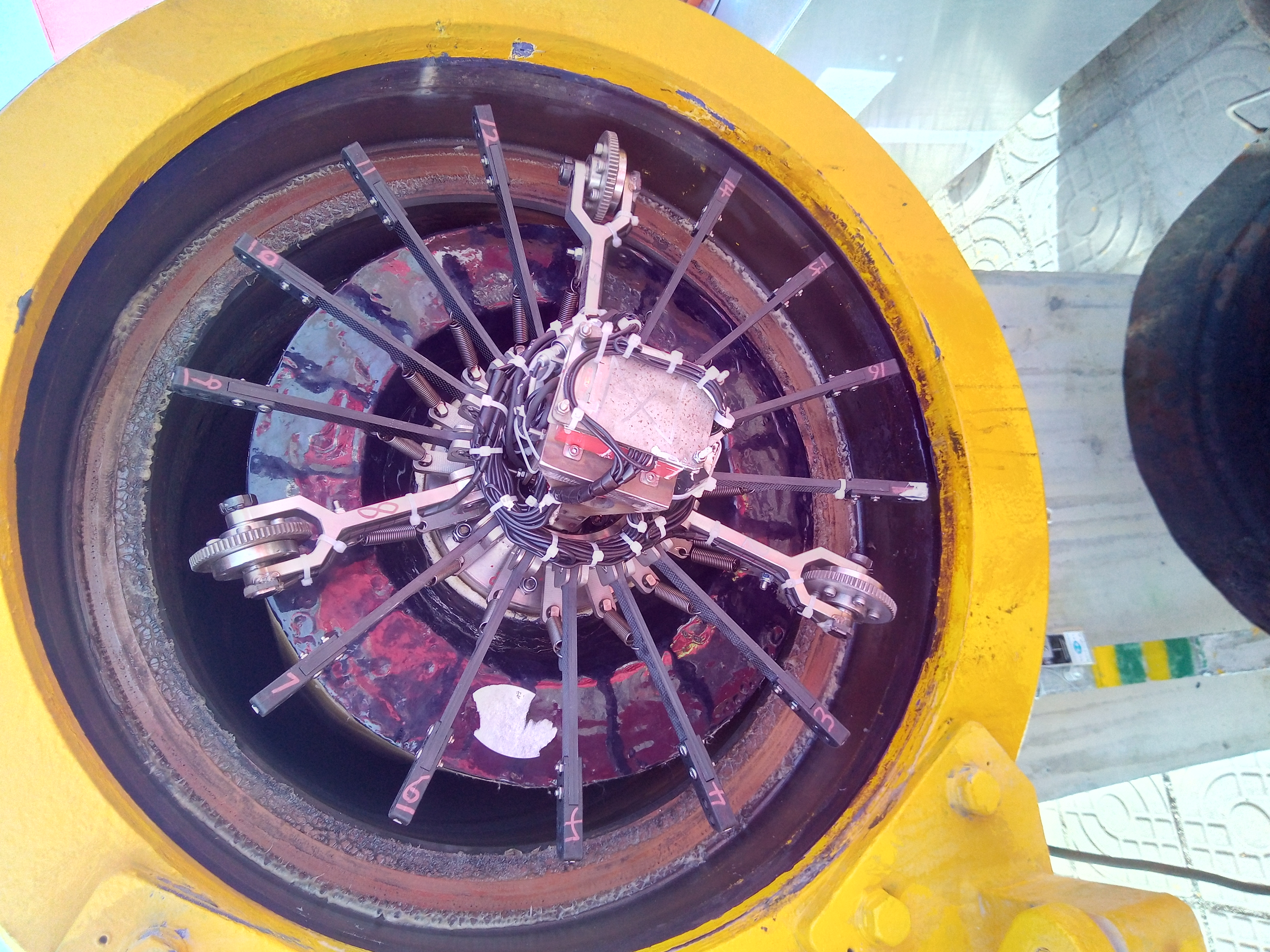

The Dina Φ457 bimetallic composite pipe inspected this time starts from the Dina 2-9T valve station and ends at the Dina 2-1 gas gathering station. It was commissioned in December 2015, with a length of 5.24 kilometers and an operating pressure of 9.3 MPa. The pipe employs mechanical bimetallic composite material (L415N+316L) and transports natural gas, condensate, and water. Since its construction, this pipeline has never undergone internal inspection. In August 2023, the Dina Oil and Gas Production Management Area used a foam pig to clean the pipeline, but the foam pig got stuck at a deformed position during operation, confirming severe lining deformation within the pipeline. In response, the inspection team customized the inspection tool, conducted multiple simulations of the inspection plan, and investigated potential issues during the inspection process one by one. They thoroughly assessed the difficulties and risk points of this operation to ensure the successful completion of the foam geometry internal inspection work.

At the beginning of the operation, since the inspected pipeline was a trunk gas transmission line, to avoid affecting production, the project had only one day before the start of the maintenance period, which greatly compressed the operation time. Meanwhile, the maintenance window period occurs only once a year, meaning this inspection must succeed. Through continuous discussions and repeated deliberations with the owner, all preparations were confirmed, and emergency response plans were prepared. Ultimately, the foam pig and foam geometry internal inspection tool were operated on July 21. The data during the equipment operation was complete and valid, and the probe coverage was intact. Through data analysis, two large deformation points were successfully located and replaced, with the maximum deformation point being 22.2% OD. The field measured data matched the inspection data, successfully demonstrating T-ALL Inspection's further breakthrough in the field of bimetallic composite pipe lining collapse detection technology.

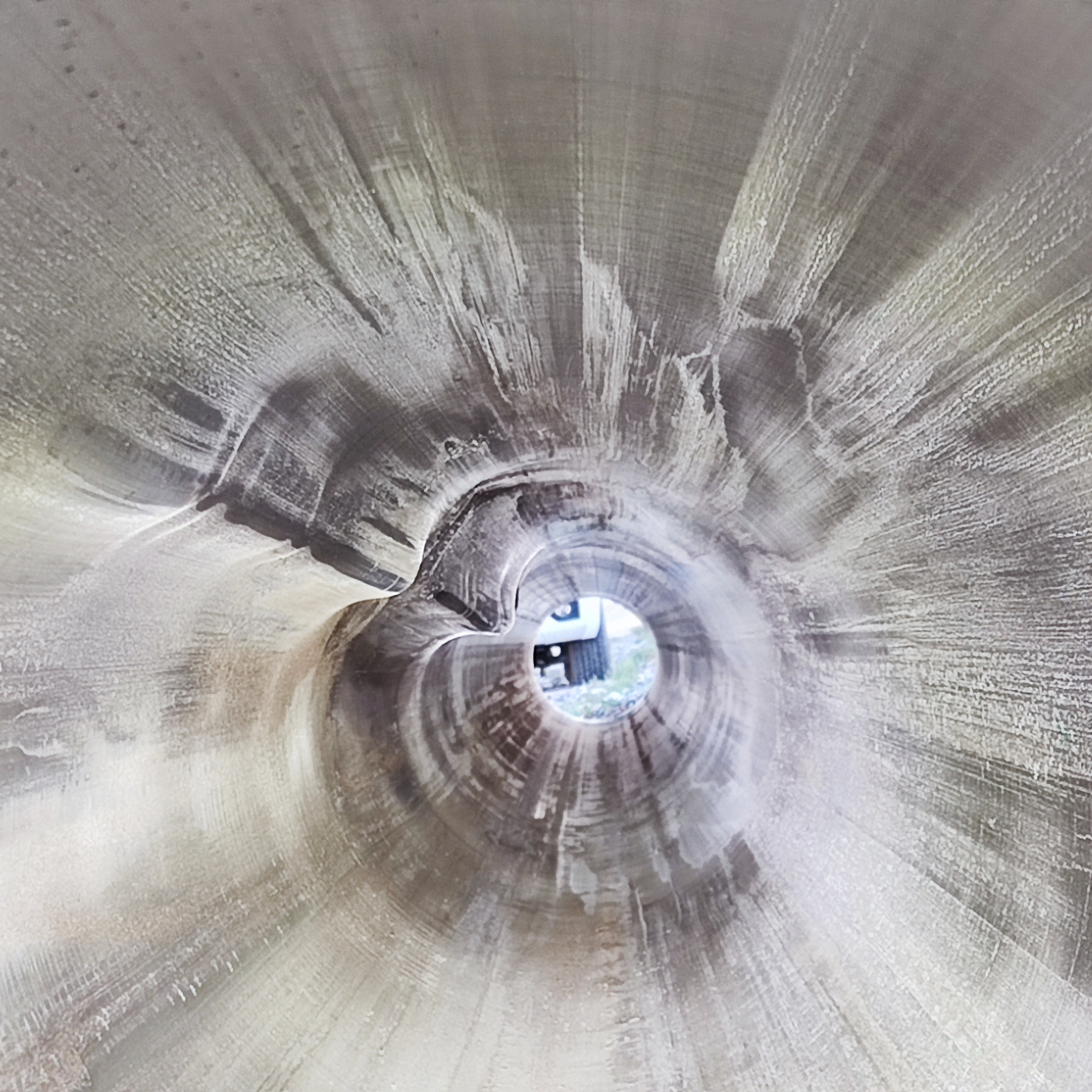

Physical Image of Lining Collapse

This internal inspection project was successfully completed through seamless cooperation with the owner and collective efforts. During the operation, the inspection personnel overcame the intense summer heat and various difficulties, successfully completing the pigging and inspection work within one day and the deformation point location and excavation work within four days, ultimately smoothly completing the project's acceptance and delivery. The successful implementation of this internal inspection project follows another successful case of the Dina Φ508 bimetallic composite pipe foam geometry internal inspection in August 2023 and accumulates more experience for inspecting more and smaller-diameter bimetallic composite pipes in the future.