At a national energy wind farm in Guangxi, the new energy inspection team successfully used a wall-climbing robot integrated with advanced AI technology to complete the weld inspection of a 120-meter wind turbine tower for the first time.This achievement not only marks the formal entry of ultra-high wind turbine tower inspection into a new AI-driven era, but also demonstrates the deep application and outstanding value of AI technology in complex on-site industrial scenarios.

The trend toward larger turbines has become inevitable, with 120-meter and taller towers gradually becoming the industry standard.However, traditional manual inspection methods face high safety risks and low efficiency in high-altitude environments, and inspection results are easily influenced by human experience and condition.The industry urgently needs intelligent solutions that can replace manual work while providing objective, precise, and efficient decision-making support.T-ALL Inspection Group’s latest application is a direct response to these needs.

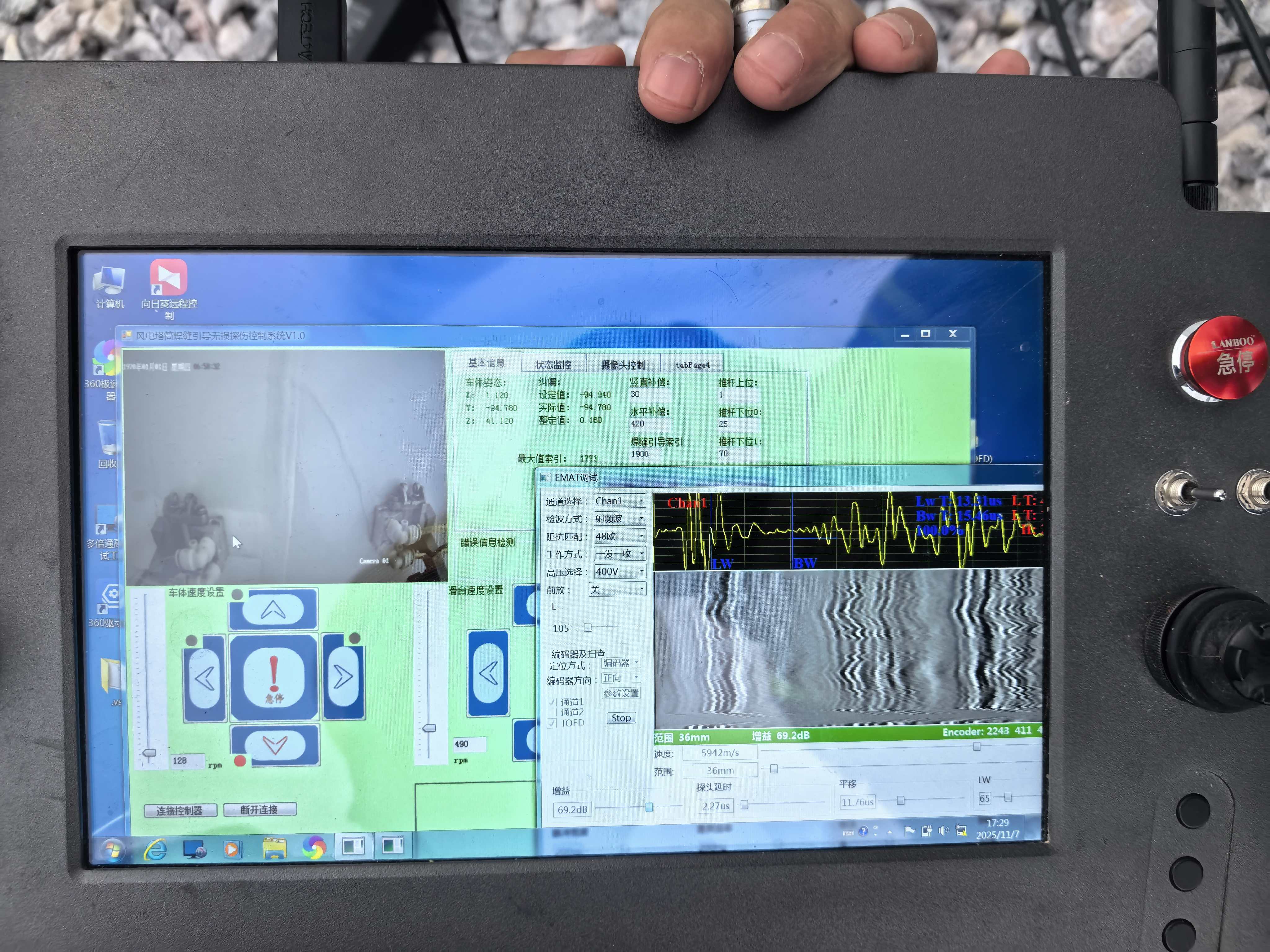

The wall-climbing robot used in this application has gone beyond the traditional limitations of a “tool,” becoming an on-site intelligent agent that integrates perception, decision-making, and analysis. Its core advantages include:

The robot is equipped with visual sensors and uses AI vision algorithms to recognize the tower surface and weld seam trajectories in real time.It can autonomously plan paths and avoid obstacles, greatly reducing manual remote control and effectively improving the automation and stability of inspections.

During inspection, the robot’s built-in AI model can analyze collected data in real time, quickly identify potential defect features, and automatically label and classify them.It converts complex data into valuable diagnostic insights, providing strong support for engineers’ decision-making.

Relying on deep learning algorithms, the robot continuously optimizes its performance.As inspection data accumulates, its defect recognition model becomes more accurate and analysis efficiency steadily improves—truly achieving “the smarter it works, the smarter it gets.”

In the real operational environment at 120 meters, this “AI inspection expert” demonstrated exceptional performance.It not only completed the full climbing inspection smoothly but also, thanks to its intelligent analysis system, quickly and accurately identified subtle weld seam features.The robot generated a comprehensive report integrating quantitative data and intelligent diagnostic recommendations.From climbing inspection to data analysis, AI was deeply integrated throughout, achieving a significant leap from “inspection automation” to “intelligent analysis.”

This practice successfully validates a practical path for AI implementation in complex industrial scenarios.The wall-climbing robot inspection of wind turbine towers is not simply routine high-altitude work; it innovatively embeds AI technology into the full-cycle safety management of wind power assets.This pioneering application highlights the tremendous potential of “AI + Industry” integration.It not only builds a reliable intelligent safety shield for wind power facilities, effectively enhancing precision and refinement in safety management, but also provides the energy sector with a highly practical and scalable model for digital transformation.

Looking ahead, T-ALL Inspection Group will continue to increase investment in AI model iteration and upgrades, uphold its spirit of innovation, and lead with advanced technology to safeguard the safe, efficient, and sustainable development of the energy industry.