With the completion of the excavation and verification work on the China–Myanmar Gas Pipeline (Duyun–Hechi section) operated by PipeChina Southwest Pipeline Company, T-ALL Inspection successfully concluded the 1016 mm large-diameter MFL in-line inspection project, providing yet another solid safeguard for the safe and stable operation of the pipeline.

During the inspection, the advanced self-adjusting velocity control system ensured precise speed regulation, keeping the inspection tool operating steadily within the optimal range of 4–5 m/s, which provided a solid technical foundation for complete and accurate data acquisition.

The inspected distance totaled 208.183 km, with an overall run time of 13 hours and 52 minutes, during which the inspection tool remained in stable operation and achieved full-coverage data collection without any missing segments. Notably, this project marks another successful deployment of T-ALL Inspection’s 1016 mm large-diameter composite inspection tool, further strengthening the company’s leading position in this field.

Upon receiving the work notification, T-ALL Inspection immediately activated the rapid-response mechanism, established a dedicated task force, and convened a special coordination meeting for the inspection of the Duyun–Hechi section.

The team carried out a comprehensive deployment covering:

• rapid mobilization of personnel and equipment

• compliance procedures for work commencement

• site survey and marker placement

• full-scale tool calibration

• standardized cleaning runs and marker installation

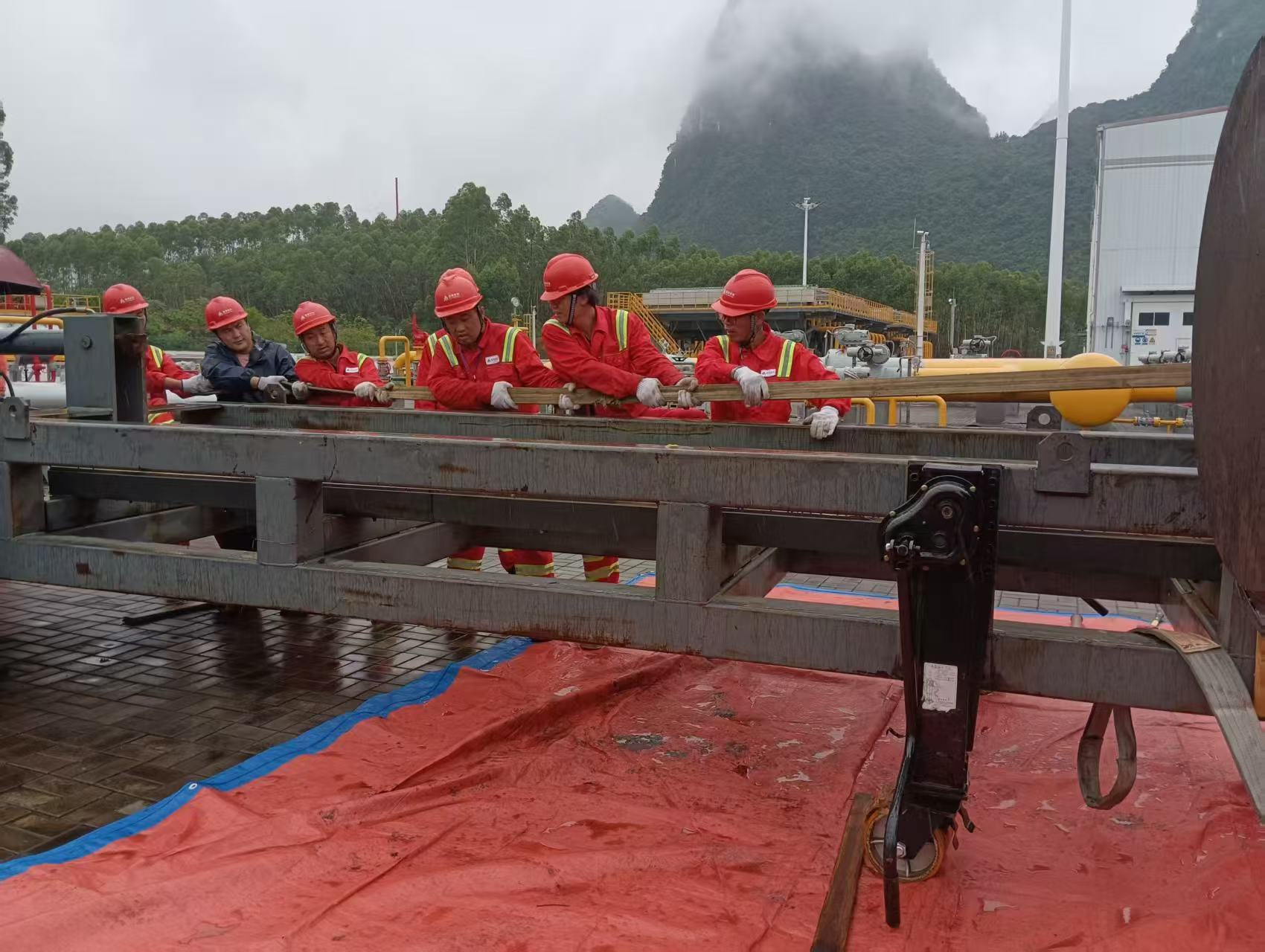

• tool launching & receiving operations

• real-time tracking and monitoring

• post-run data processing and excavation verification

Facing potential challenges such as operating conditions and technical coordination, T-ALL Inspection worked closely with the client to analyze risks, develop contingency plans, and establish a strong collaborative front to ensure smooth project execution.

Given the tight schedule and complex operating conditions, T-ALL Inspection deployed a composite inspection tool to perform MFL inspection immediately following the cleaning run, integrating:

• geometry inspection

• magnetic flux leakage (MFL) inspection

• IMU mapping

This “one run, multiple datasets” approach significantly shortened the project cycle and minimized impact on normal gas transmission.

The 1016 mm composite inspection tool demonstrated exceptional performance in key technical indicators, including signal stability, magnetization strength accuracy, circumferential/axial spacing design, data completeness, and defect detection sensitivity.

All inspection results fully met national and industry standards, reflecting T-ALL Inspection’s strong technical capabilities.

During the operation, the team encountered severe weather, including continuous rainfall, road collapses, and landslides, posing major challenges to on-site work.

In response, T-ALL Inspection and the client jointly established an Emergency Response Coordination Mechanism, forming a unified emergency team that shared real-time weather alerts, road conditions, and essential operational information. The inspection plan was dynamically adjusted based on field conditions, enabling 24-hour continuous operations.

With determination, resilience, and efficient execution, the team completed the full inspection task in just 15 days, setting a new benchmark of efficiency known as “T-ALL Speed” in the field of large-diameter in-line inspection.

The successful completion of this inspection project demonstrates not only the reliability of T-ALL Inspection’s MFL technology under complex conditions, but also the effectiveness of multi-party collaboration.

Looking ahead, T-ALL Inspection will continue to uphold a customer-centric approach, supported by professional expertise and a strong sense of responsibility. The company remains committed to safeguarding the security of national energy infrastructure and contributing T-ALL’s strength to the protection of China’s vital energy arteries.