T-ALL Inspection Makes Solid Strides in International Pipeline Inspection Market with Successful Internal Pipeline Inspection of Three 10-inch Pipelines in Ecuador in December 2024

In December 2024, the T-ALL Inspection pipeline inspection project team successfully completed the internal inspection of three 10-inch pipelines in Ecuador, marking a solid step forward for T-ALL Inspection in the international pipeline inspection market!

Just as a triangle has a stable and enduring structure, the close collaboration and deep friendship between T-ALL Inspection and its partners were fully demonstrated on the Ecuadorian project. From the official launch of the project on September 30th, to the intensive mobilization of personnel and equipment, to the efficient completion of pigging tasks by the team on October 27th, each step laid a solid foundation for subsequent inspections. Entering November, the project entered a critical stage, especially from November 16th to November 19th, when the team not only successfully completed equipment debugging and repairs but also smoothly advanced on-site inspection, data downloading, and evaluation work. Each step embodied the team's professionalism and hard work. Finally, on December 2nd, the T-ALL Inspection project team submitted a detailed inspection report, marking the successful conclusion of the project. Throughout this process, T-ALL Inspection and all parties not only overcame cultural differences and achieved resonance but also witnessed the power of teamwork together, creating an extraordinary journey full of challenges and achievements.

Outstanding Performance Amid Multiple Challenges

Natural Environment: The project site is located in the tropical rainforest, with harsh conditions. The team faced high temperatures, intense ultraviolet rays, and infestations of insects, snakes, and rats, but none of these obstacles stopped their progress.

Social Environment: Due to the arrival of the dry season, frequent power outages and water cuts in Ecuador posed great challenges to the project plan. However, with firm beliefs and flexible strategies, the project team successfully overcame these difficulties.

Pipeline Environment: The short pig launcher and receiver, medium temperatures as high as 85°C, and extremely high water content presented severe challenges in the complex pipeline environment. But the project team and the client's personnel worked together, solving one problem after another through frequent interactions and efficient collaboration.

Innovation and Technological Advancements

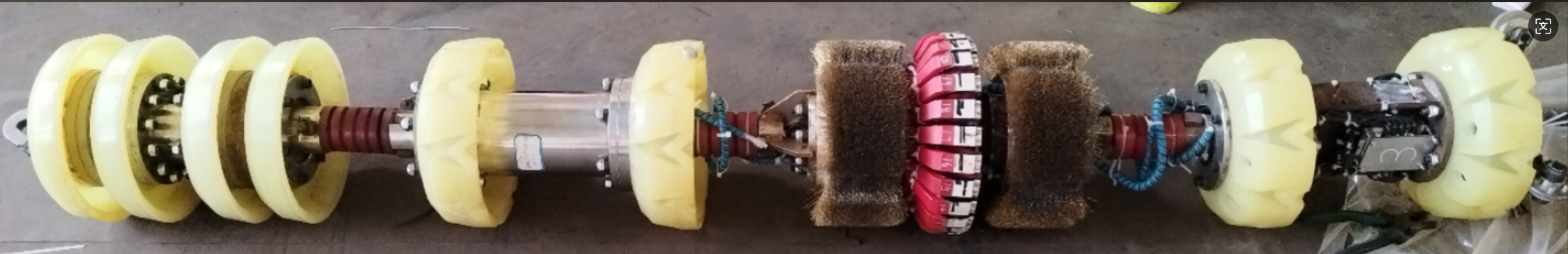

To accurately measure the temperature of the pipeline medium, the project team modified the pigging tool by installing a temperature recorder, successfully recording the medium temperature and providing a reliable basis for subsequent data analysis.

Temperature Recorder

Facing challenges such as poor social conditions and unstable working hours, the project team flexibly adjusted working hours, staying on duty no matter how late or where, to ensure the smooth progress of the work.

During equipment selection, pull testing, and other processes, the team proceeded with caution, handling every detail properly to ensure success. To address the issue of short pig launcher and receiver, the project team modified the equipment, shortening its length to successfully meet on-site requirements.

The success of the Ecuadorian project not only showcases T-ALL Inspection's technical capabilities in the field of pipeline inspection but also embodies its perseverance and teamwork spirit in the face of challenges. In the future, T-ALL Inspection will continue to uphold this spirit, providing more customers with quality services and solutions!