Get Free Risk Analysis

Follow T-ALL

On April 13, 2025, T-ALL Inspection's internal inspection team brought good news by successfully completing the downloading and preliminary interpretation of the internal inspection data for the Tumushuke gas transmission pipeline. The data is complete and valid, marking the successful conclusion of the on-site internal inspection operations for the Tumushuke gas transmission pipeline. It is worth mentioning that the technology used in this inspection is Super Magnetic Flux Leakage (SMFL). This is another successful application of this technology by T-ALL Inspection in this field, following the internal inspection of the Yaya oil pipeline.

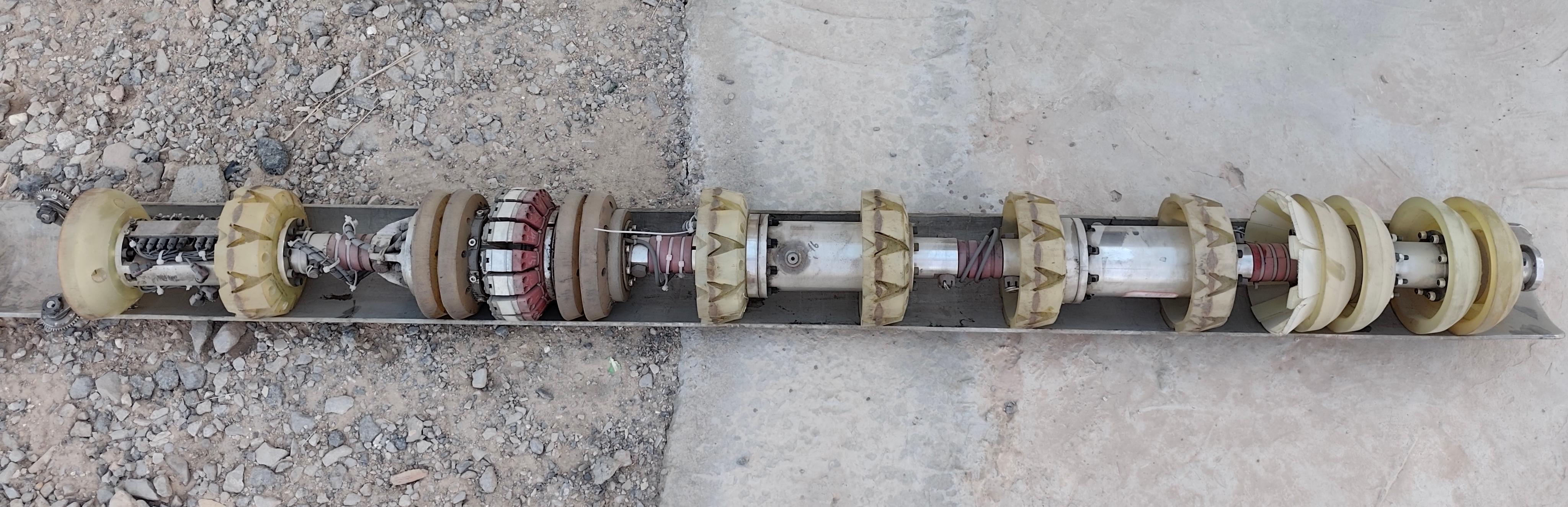

The Super Magnetic Flux Leakage (SMFL) internal inspection technology utilizes a strong magnetic field to magnetize the pipeline through gas transmission, eliminating the need for physical contact with the inner wall of the pipeline. This avoids the high resistance and low passability associated with traditional steel brush magnetic induction, effectively reducing the weight of the inspection device and enhancing its passability. It also mitigates the risk of high resistance encountered with traditional steel brush magnetic induction, allowing the device to pass through 1.5D elbows with ease. This makes it particularly suitable for inspecting low-pressure, low-flow, small-diameter pipelines with numerous elbows that are prone to blockages.

The Tumushuke gas transmission pipeline has a total length of 39.24 km, a design pressure of 6.3 MPa, and is made of L245 seamless steel pipe with an outer diameter of 168.3 mm and a wall thickness of 5.6 mm. It was commissioned in August 2013 and employs impressed current cathodic protection. This inspection serves as the baseline inspection for the pipeline.

During the inspection process, T-ALL Inspection's operational team demonstrated a high level of professionalism and teamwork, with each workgroup fulfilling their responsibilities and working closely together. The team completed four pigging operations, one geometric internal inspection, and one Super Magnetic Flux Leakage internal inspection. Additionally, the inspection team maintained close communication with local relevant departments to promptly resolve various issues encountered during the inspection, ensuring the smooth progress of the work.

The successful completion of the Super Magnetic Flux Leakage (SMFL) internal inspection of the Tumushuke gas transmission pipeline marks another success for T-ALL Inspection in small-diameter pipeline internal inspection projects.

Super Magnetic Flux Leakage is T-ALL Inspection's third brand and market segment in the industry, following full-foam and single-trip ultrasonic technologies. It specifically addresses the issues of frequent elbow blockages and low-pressure, low-flow conditions in small-diameter pipelines, laying the foundation for subsequent advancements in even smaller-diameter pipeline internal inspection technologies.

T-ALL Inspection will continue to adhere to the concept of innovation-driven development, continuously exploring and applying new technologies and methods, and contributing more wisdom and strength to ensuring the safe operation of national energy pipelines.