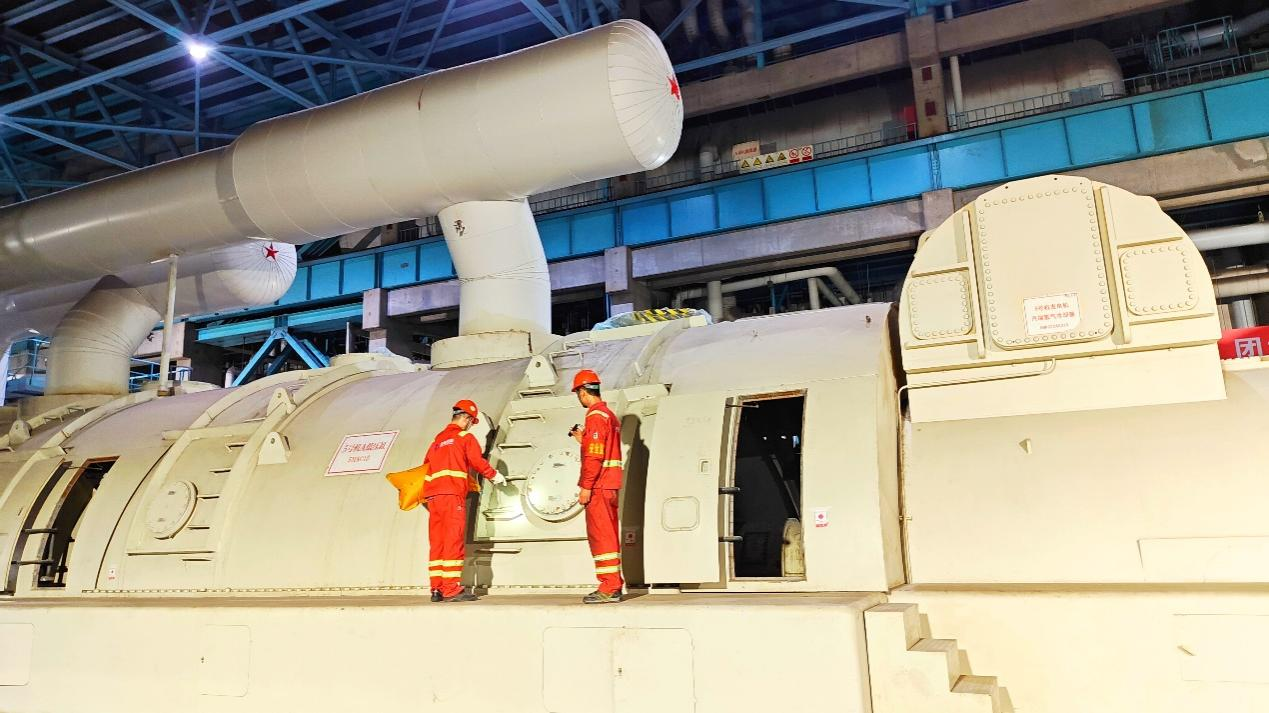

On September 29, 2024, the helium leak detection team of T-ALL Inspection successfully completed the leak detection and sealing work for the tightness of the vacuum system of the No. 5 630MW generator set at Anhui Luoneng Power Plant. Faced with the challenges of the complex process flow, poor vacuum tightness, high pressure drop, and the dilemma of unsuccessful detection and treatment attempts by multiple manufacturers for the No. 5 unit, T-ALL Inspection successfully overcame this difficulty with its professional technical solutions and efficient execution, bringing tangible benefits to the client.

Overcoming Difficulties and Embracing Challenges

The No. 5 generator set at Anhui Luoneng Power Plant, as an important piece of equipment that has been in service for many years, faces multiple challenges in its vacuum system: Complex Process Flow: The vacuum system consists of numerous pipes, valves, flanges, etc., with leak points located in concealed positions, posing great difficulties for detection and maintenance work. Poor Vacuum Tightness: The system leakage problem is particularly severe, with a pressure drop reaching 290Pa/min. This not only affects the operating efficiency of the unit but also poses a threat to safe production and causes losses to the client's economic benefits. Difficulty in Leakage Treatment: Previously, multiple vendors attempted to solve this problem but failed, causing significant distress to the client and eroding their confidence in resolving the vacuum issue. Tight Timeline: The client hopes to resolve the vacuum problem as soon as possible to avoid affecting unit operation and ensure production stability. Careful Planning, Overcoming Difficulties, and Efficient Treatment In response to the pain points of the No. 5 unit, the helium leak detection team of T-ALL Inspection formulated a thorough detection plan and efficient treatment solution: Comprehensive Inspection Route: A detailed inspection route was developed to ensure that no suspicious leak points were overlooked. Each inspection point was recorded and marked in detail to provide a basis for subsequent treatment. Shift Work: To meet the client's urgent timeline requirements, a shift work model was adopted, with personnel working continuously to continuously conduct detection and verification to ensure timely identification and resolution of issues. Repeated Detection and Verification: Each detection point underwent multiple detections and verifications to ensure the accuracy and reliability of the detection results, avoiding misjudgments and omissions. Targeted Leak Sealing Solutions: Different leak sealing solutions were formulated for different leak points, and advanced sealing materials and processes were used to ensure the sealing effect and restore vacuum levels. Systematic Treatment Recommendations: Based on the detection results and treatment solutions, systematic treatment recommendations were proposed to help the client establish a comprehensive vacuum system maintenance system to address leakage issues. Facing the many challenges of this project, the team was not intimidated by difficulties and worked tirelessly day and night. With their superb skills and perseverance, they overcame numerous obstacles and ultimately successfully completed the detection task. During this rigorous and meticulous detection process, the team not only detected 20 major leak points but also accurately identified multiple minor leak points, providing important safeguards for the safe operation of the power plant. It also demonstrated the efficient capabilities and professional spirit of the helium leak detection team of T-ALL Inspection.

Future Prospects and Continuous Innovation As the project winds down, Anhui Luoneng Power Plant has highly praised the professional capabilities and efficient service of the helium leak detection team of T-ALL Inspection. This not only validates our technical strength but also demonstrates our firm commitment to fulfilling our promises to clients. T-ALL Inspection will continue to adhere to the service philosophy of "professional, precise, and efficient," relentlessly exploring and innovating to inject solid technical strength into the safe production and sustainable development of the power industry. We cherish every opportunity for cooperation and look forward to creating brilliance with more partners.