degree of heat7

degree of heat7

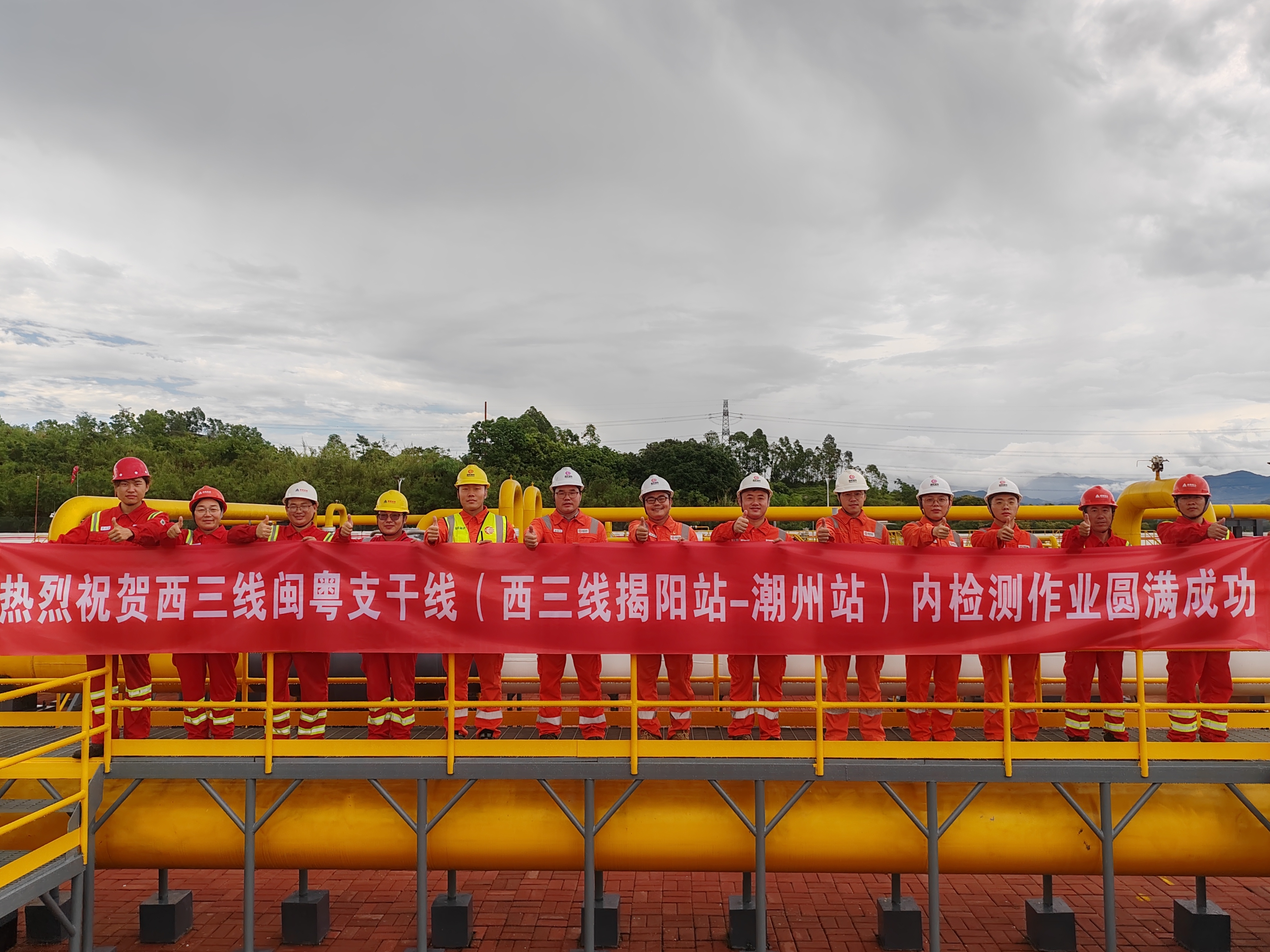

On December 17th, the full-foam internal pipeline inspection project for the Min-Yue Branch Pipeline (Jieyang-Chaozhou) contracted by T-ALL Inspection for the China National Petroleum Pipeline Corporation's South China Company successfully passed inspection. Following the record set by the Longxi Branch of Gansu Company for the longest operational distance (144km) in China, this project has once again upgraded the inspected pipeline diameter to Φ813mm, setting a new record for the largest diameter in the application of full-foam internal inspection technology for long-distance pipelines in China!

The Min-Yue Branch Pipeline (Jieyang-Chaozhou) starts at the Jieyang Station in Guangdong and ends at the Chaozhou Station, spanning a total length of 55.38km with an outer pipeline diameter of 813mm. Since its commissioning in 2020, no internal inspection had been conducted on this pipeline.

Full-Foam Geometric Inspector

Full-Foam Vortex Detector

During the midsummer, with strong support from the client, the field team overcame numerous challenges such as extreme heat. From June 25th, 2024, when the first polyurethane foam pig was launched, to July 12th when the eddy current inspector was successfully retrieved, it took 18 days to complete two runs of polyurethane foam pigs, one run of a foam geometry inspector, and one run of a foam eddy current inspector, successfully fulfilling the baseline inspection tasks for the Min-Yue Branch Pipeline (Jieyang-Chaoshan section).

Scheme Presentation and Training

Pig Launching and Receiving Site

In November, excavation and verification work were conducted at five defect locations. By comparing the field-measured data with the inspection data, it was confirmed that the axial and circumferential positioning, length, width, and depth accuracy of the five defect characteristics all met the standard requirements.

Geometry Verification

Corrosion Verification

The Min-Yue Branch Pipeline (Jieyang-Chaozhou) starts at the Jieyang Station in Guangdong and ends at the Chaozhou Station, spanning a total length of 55.38km with an outer pipeline diameter of 813mm. Since its commissioning in 2020, no internal inspection had been conducted on this pipeline.

Looking ahead, T-ALL Inspection will continue to enhance its technical expertise and service quality, improve its technical system, and strive to provide clients with even better and more efficient pipeline inspection solutions. The successful implementation of the internal pipeline inspection project for the Min-Yue Branch Pipeline (Jieyang-Chaozhou section) not only demonstrates T-ALL Inspection's robust strength in independent innovation but also marks another significant breakthrough in its self-developed full-foam internal inspection technology.