degree of heat8

degree of heat8

On November 29th, the Tianshui Oil and Gas Transportation Branch of Gansu Provincial Company organized a special acceptance meeting for the foam geometry and foam eddy current internal inspection projects of the Longnan Branch Pipeline. After rigorous and detailed reviews of the acceptance materials and inspection results submitted by T-ALL Inspection, the experts attending the meeting unanimously agreed that the projects had successfully passed the acceptance.

Challenges Faced in Baseline Inspection of Low-Throughput Pipelines

Baseline inspection of long-distance low-throughput pipelines has always been a major challenge for major pipeline management agencies. Taking the Longnan Natural Gas Distribution Branch Pipeline as an example, the pipeline starts from the Longnan Gas Transmission Station and ends at the Longnan Terminal Station, with a total length of 94km, a pipe diameter of 219mm, and a design pressure of 6.3MPa. The daily gas transmission volume of the pipeline is low, with a conventional transmission volume of about 20,000 standard cubic meters per day. The pipeline is surrounded by mountains and valleys with significant elevation differences. During crossings of highways, bridges, and high-voltage lines, the pipeline inspection work faces great challenges. No internal inspection has been carried out since its commissioning.

Innovative Full-Foam Solution

Since the proposal of eddy current internal inspection technology, many domestic and foreign inspection agencies have conducted various forms of attempts on different pipelines, media, and operating conditions. However, due to its limitations in only detecting internal corrosion of pipelines and having a significant gap in detection accuracy compared to conventional magnetic flux leakage (MFL) detection, it is more suitable for short-distance pipeline inspection operations where conventional MFL detection cannot be performed. Successful cases in the field of long-distance pipeline inspection are rarely heard. T-ALL Inspection innovatively proposed full-foam internal inspection technology, which, with its lighter weight and good passability (local deformation of 35%OD), can meet the technical conditions for the first internal inspection operation of low-throughput pipelines.

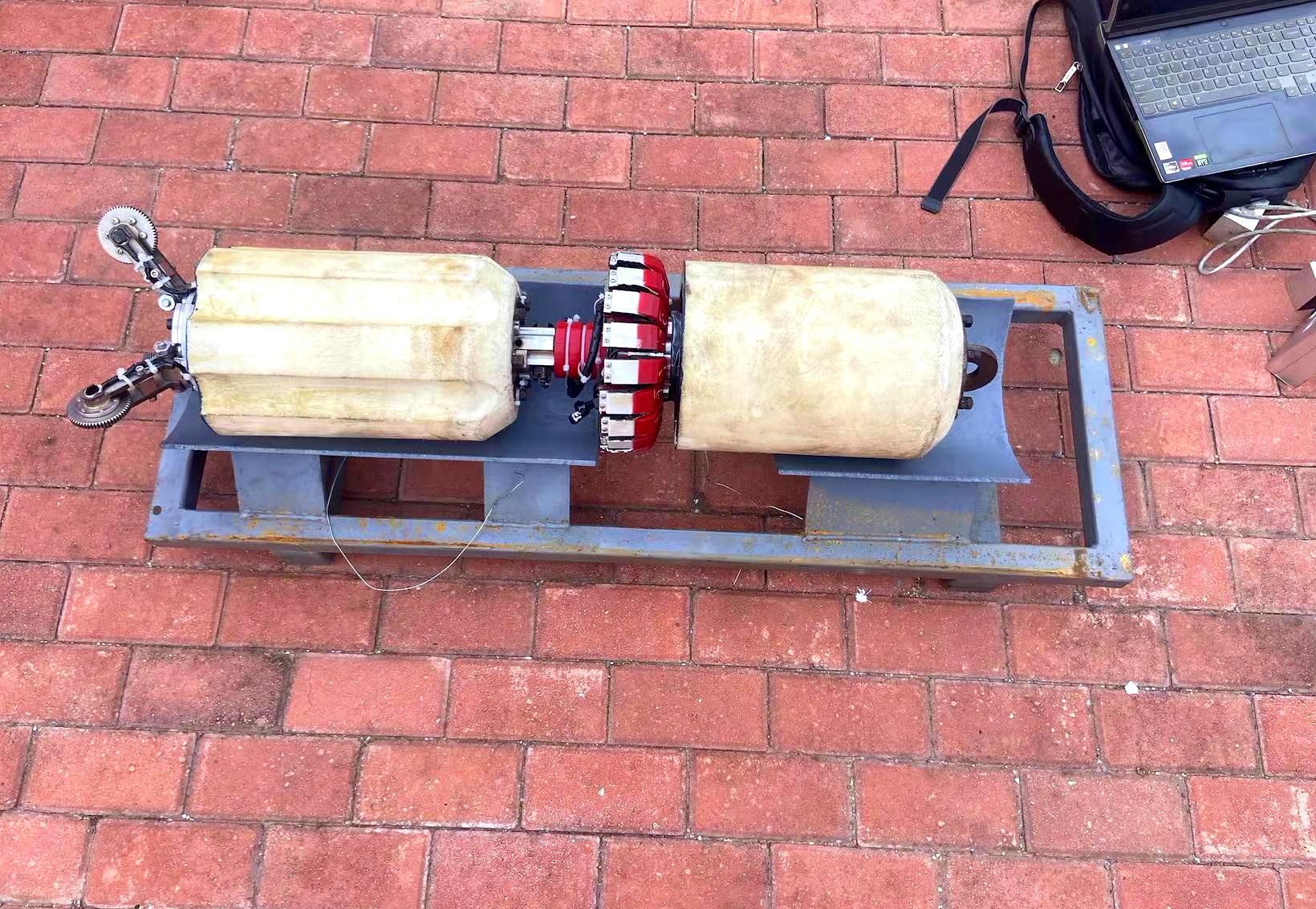

Foam Geometry Inspector

Foam Eddy Current Inspector

Field Inspection Implementation

The field inspection operation of the Longnan Branch Pipeline began on June 20th, 2024, with the launch of the first polyurethane foam pig, and ended on August 3rd with the successful retrieval of the foam eddy current internal inspector. It lasted for 44 days, with one pig, one foam geometry inspector, and one foam eddy current inspector launched during the inspection period. With the strong support of the owner, the field team rose to the challenge, overcame a series of challenges such as high temperatures, heavy rain, and night-time pig tracking, and ultimately successfully ensured the completion of the inspection operation.

Longnan Terminal Station Operation Site

Excavation Verification and Integrity Assessment

The owner organized a third-party unit to conduct excavation verification for the defect locations reported by T-ALL Inspection. After confirmation, the defect points were accurately located at the site, and the deviation values between the verification results and the inspection data were within the standard specified range, marking the successful completion of this inspection operation.

Based on the results of this internal inspection, T-ALL Inspection conducted an integrity assessment of the Longnan Branch Pipeline, scientifically evaluated the development of metal loss within the next five years, and provided maintenance suggestions in combination with the relevant provisions of the "Law of the People's Republic of China on the Protection of Oil and Natural Gas Pipelines" and "GB 32167-2015 Specification for Integrity Management of Oil and Gas Pipelines". This provided an important basis for the owner to better carry out pipeline integrity management work.

Summary of Full-Foam Internal Inspection Technology

The internal inspection operation of the Longnan Gas Transmission Branch Pipeline is a successful case of using full-foam eddy current inspection technology for baseline inspection of long-distance long-transmission pipelines in China. It has accumulated rich experience for the company in conducting internal inspection work on complex pipelines and provided new ideas for subsequent promotion of baseline inspection operations for difficult pipelines in China.

Based on the actual field operations, we believe that the full-foam internal inspection technology still has room for improvement in terms of detector endurance and ground-based tracking technology. T-ALL Inspection will continue to increase investment and actively carry out scientific research to develop technical means and inspection equipment that are more suitable for baseline inspection of long-distance low-throughput pipelines.