For casing and tubing products, our supervision process prioritizes test and product quality through:

Quality management system effectiveness verification Testing compliance and product specification conformance Factory

Factory Inspection

Inspection  Inspection

Inspection  Well Control

Well Control Coating

Coating  API Workshop Standardized

API Workshop Standardized Running

Running Connection

Connection  Synchronized MFL Inspection

Synchronized MFL Inspection

For casing and tubing products, our supervision process prioritizes test and product quality through:

Quality management system effectiveness verification Testing compliance and product specification conformance

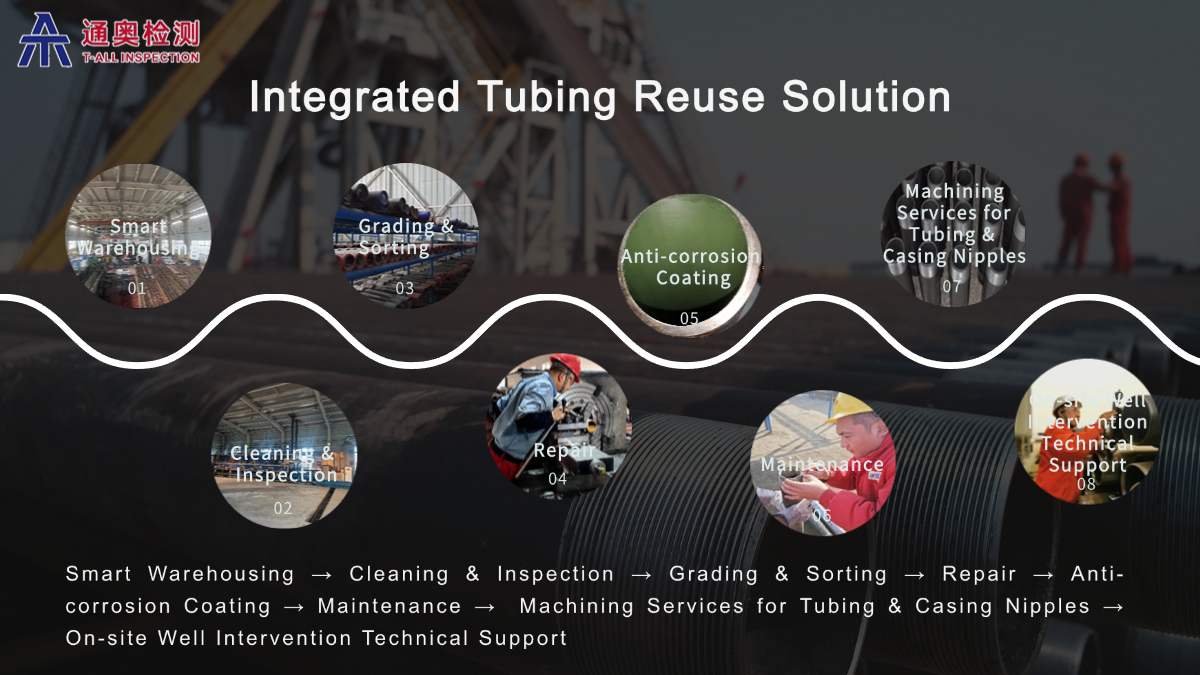

Providing asset evaluation services centered on casing/tubing inspection, supported by:

Coverage: Tubing, casing, sucker rods, coupling tools, executing full-process technical services at regional bases per API/gas-tight thread standards:

Providing precision machining for pipe subs and downhole tool accessories used in drilling, well testing, and surface construction operations, while fulfilling custom design and machining requirements for rotary shafts & disc components.

Comprehensive anti-corrosion solutions developed with Southwest Petroleum University:

Design and construction services per API/QHSE standards:

Indentation-free makeup services for all casing/tubing sizes:

Post-makeup helium leak detection verifying gas-tight integrity of casing/tubing (2-7/8" to 18-5/8")connections under simulated downhole conditions On-site.

Real-time non-destructive testing integrated with tubing extraction processes using magnetic flux leakage technology to assess pipe integrity without interrupting rig operations.