Asset integrity management consulting

Asset integrity management consulting

Measuring instrument management service

Measuring instrument management service

ECITB-Authorized Flange Management Training

ECITB-Authorized Flange Management Training

Technical Qualification Certification Training for Tubular Thread Inspectors (Level I and Level II)

Technical Qualification Certification Training for Tubular Thread Inspectors (Level I and Level II)

Training on Non-destructive Testing (MT, UT, FLT) for Tubular Goods

Training on Non-destructive Testing (MT, UT, FLT) for Tubular Goods

Carbon Peaking and Carbon Neutrality certification consulting

Carbon Peaking and Carbon Neutrality certification consulting

Carbon Asset Development and Trading

Carbon Asset Development and Trading

ESG Consulting

ESG Consulting

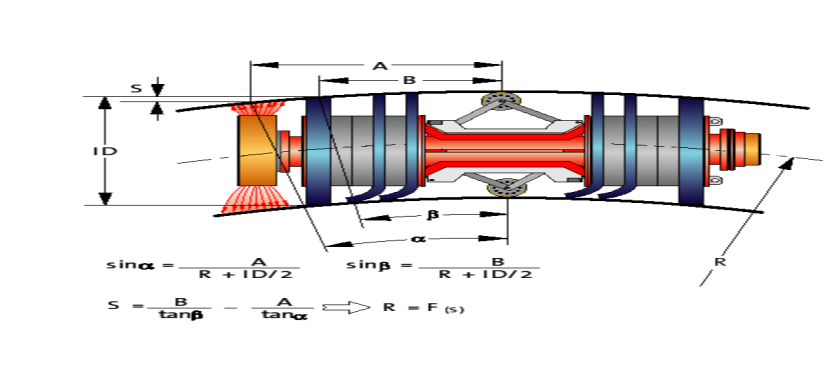

Pipeline Intelligent Internal Inspection

The Pipeline Intelligent Internal Inspection Technology is using in-tube medium to drive detector to run in the pipeline, so as to record the coordinates and dimensions of the pipeline in real time and inspect the damages such as deformation, corrosion, leakage of pipelines. It can measure and analyze wall variations and locate defects efficiently. Anton Inspection Group is an independent third-party inspection organization with independent service team, which carried out research on pipeline internal inspection technology earlier in China.

technical feature

· High inspection reliability with double assurance of Magnetic Flux Leakage (MFL) and Electro Magnetic Acoustic Transducer (EMAT).

· Accuracy of locating geographic coordinates and defects of pipelines.

· Inspecting the damages such as deformation, corrosion, leakage of pipelines.

· High inspection efficiency of up to 5 m/s running speed and over 1000 km of single running mileage with continuous transportation in the pipeline.

· Integrated intelligent internal inspection services, including pipe cleaning, geometric inspection, magnetic flux leakage inspection, excavation verification, etc.

service performance

· Domestic customers: Tarim Oil Field, Southwest Oil and Gas Field, West Pipeline Branch, West-East Gas Pipeline Branch, etc.

· 10 years of service experiences inspecting over 10,000 km of pipelines.